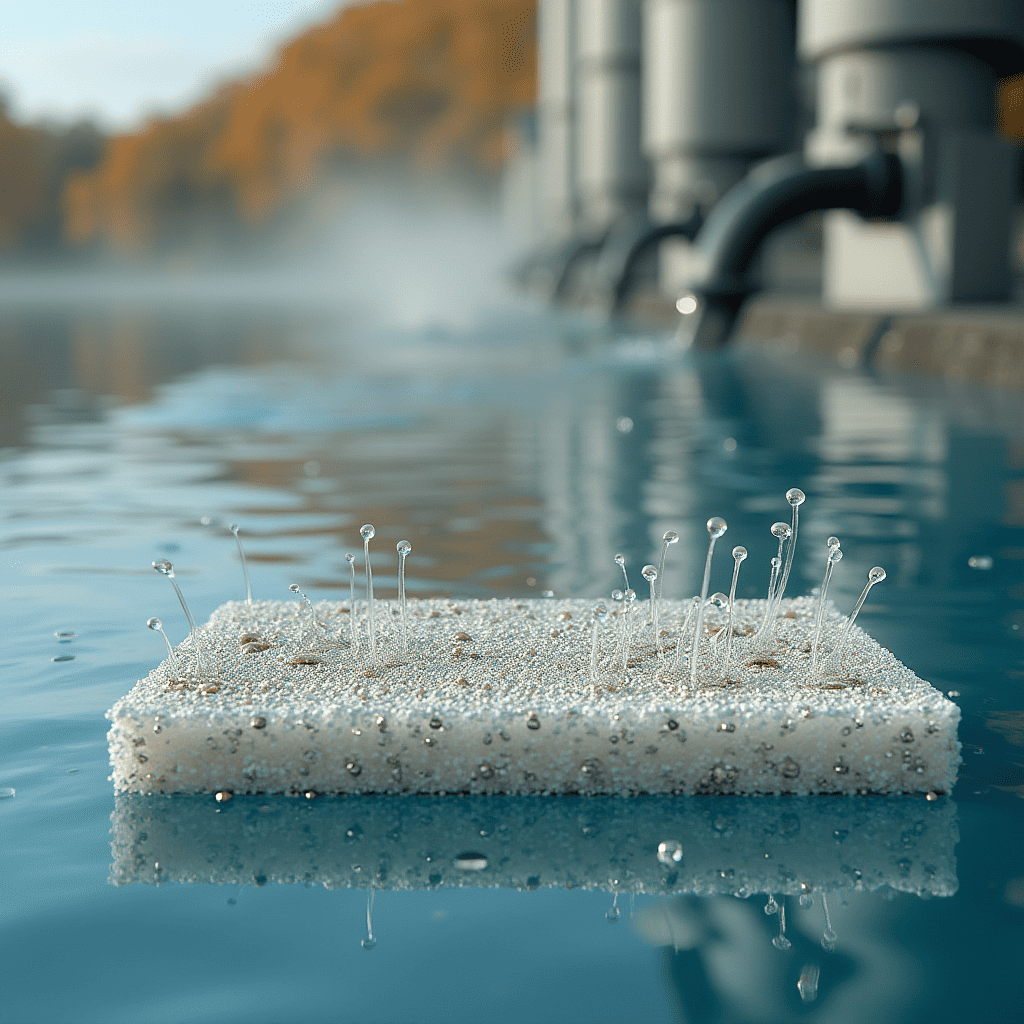

Scientists have created a “smart” sorbent that cleans water and returns valuable resources to production.

How the nano-sponge works

It has a porous cellulose base with a metal oxide nanoparticle coating. The principle is a chemical trap:

- Heavy metals (lead, copper, zinc) bind to the surface of particles through ion exchange.

- Phosphates are captured due to electrostatic attraction.

The material functions on a pH contrast — when the acidity of the environment changes, the sponge captures or releases pollutants, allowing it to be used repeatedly:

- Sorption is activated in neutral water.

- In an acidic environment (pH <4), metals are released.

- In an alkaline environment (pH >10), phosphorus is released.

“We’ve turned a problem into a resource. Instead of burying toxins, we are reusing them,” says Vinayak Dravid, project leader.

Tests in Chicago

Metal factory effluent and agricultural fertilizer pollute the Great Lakes.

Problem:

- The Environmental Protection Agency (EPA) allows up to 1.3 ppm of copper in water.

- Algae blooms were observed because phosphorus levels must be under 0.1 ppm to prevent them.

Solution:

- StormTrap LLC, a company specializing in stormwater treatment, introduced filters based on the sponge into collectors.

- Result: 99% removal of copper and zinc and 94% of phosphates per cycle.

The nano-sponge tackled the algae bloom problem.

Resources vs. ecology

Phosphorus ores are being depleted by 3% each year. At the same time:

- 22 million tons of phosphates are washed into the oceans.

- The extraction of 1 ton of phosphorites emits 5 tons of carbon dioxide.

Re-use example: Metals collected from Chicago’s wastewater are sent to the BatteryCorp plant for battery production.

Development of multipurpose technology

The development of the nano-sponge is the result of many years of research, a kind of “Swiss Army Knife” in the world of water purification, combining various functions:

- 2019: OHM-sponge for oil collection.

- 2021: PEARL membrane for extracting phosphates.

- 2023: Technology for removing lead down to 2 ppb.

- 2025: Multi-tasking Nano-SCHeMe platform.

“Previously, toxic dirt was obtained after cleaning. Now it is raw material for industry,” says Kelly Matuszewski, a graduate student.

Future: from microplastics to rare earth metals

Plans for 2026-2030:

- Marine testing in the Gulf of Mexico.

- Integration with desalination systems.

- Creation of household filters for less than $10.

The project encountered a paradox: the more effective the cleaning, the greater the contribution of agriculture to pollution. The scientists’ answer is mobile units for farms that intercept runoff before it enters rivers.